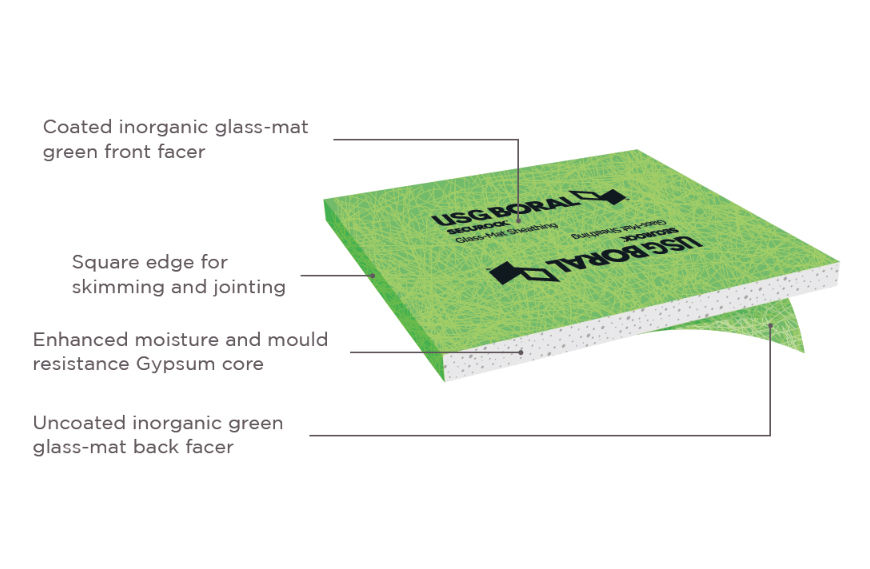

USGKnauf SECUROCK® Glass-Mat Sheathing are non-combustible, moisture- and mould-resistant panels for wet areas, backer tile, and semi-exterior applications. The panels have inorganic non-woven glass mat facers that repels water and feature square edges. The front facer glass mat is primed and engineered to accept the application of USGKnauf finishing systems.

For more information on Exterior Applications, please contact your local USGKnauf sales representative.

Features

Non-combustible, Water, Moisture and Mould-resistant- Inorganic non-woven glass mat front and back facers, offering exceptional water and weather resistance.

- Patented Mold Tough™ technology with moisture and mould-resistant gypsum core.

- A1 Non-combustible according to EN 13501-1+A1:2013 and BS 476 Part 4 1970.

- Mould-resistant: Scores a 10 (highest) when tested in accordance with ASTM D3273.

- Meets or exceeds the requirements of ASTM C1177 (Standard Specification for Glass Mat Gypsum Substrate for Use as Sheathing).

- Meets or exceeds the requirements of ASTM C1178 part 5.2.5 (Standard Specification for Coated Glass Mat Water-Resistant Gypsum Backing Panel).

- Meets or exceeds the requirements of EN15283-1 (Gypsum boards with fibrous reinforcement - Part 1).

- Conform to the provisions of the European CPR-Construction Products Regulation and related CE Marking technical requirements.

- Non-combustible core when tested in accordance to BS 476 Part 4 1970, and Class A1 non-combustible according to EN 13501-1+A1:2013.

- Simple score-and-snap, with no sawing or special tools required.

- Exposure: Can be exposed to limited-weather for up to 12 months after installation in interior and exterior applications. The product should be covered by the recommended interior or exterior finishing like EIFS, DEFS, sheathings, claddings or sidings.

- USGKnauf SECUROCK® Glass-Mat Sheathing is guaranteed for five years against manufacturing defects.

- Backed by the high-quality standards and outstanding service of USGKnauf.

- 12.7mm (1/2”) SECUROCK™ Glass-Mat Sheathing Panel.

Application Fields

Walls:- Backer tile walls in public shower, bathroom areas for commercial and residential projects.

- Non-Tile walls with high moisture and mould requirements.

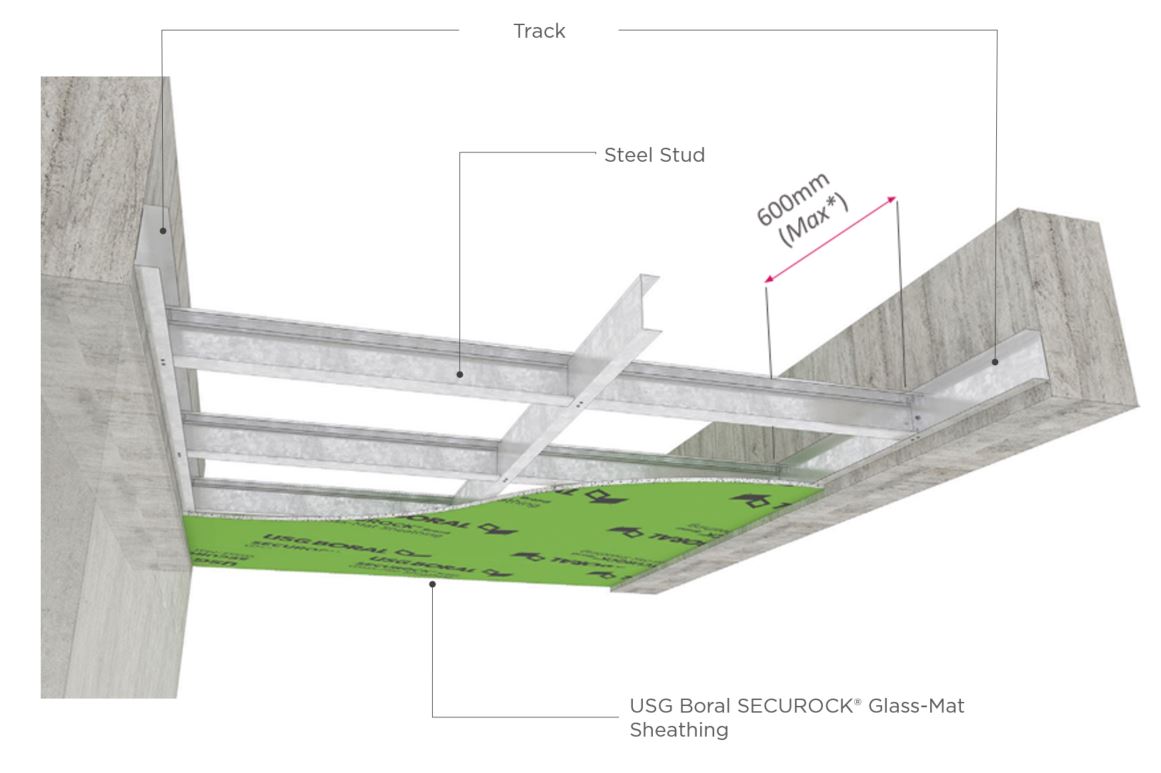

- Wet area ceilings.

- Industrial Kitchens Ceilings.

- Swimming pool ceilings.

- Exterior Ceilings.

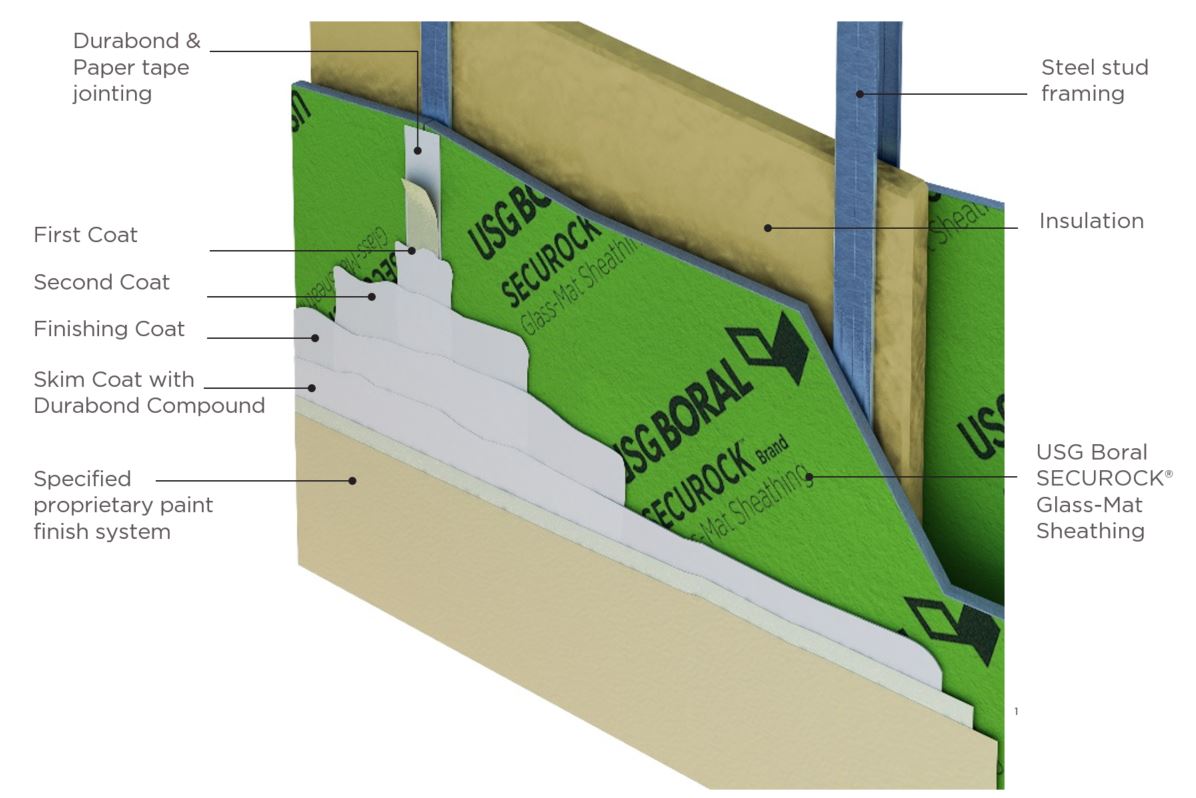

Finishing

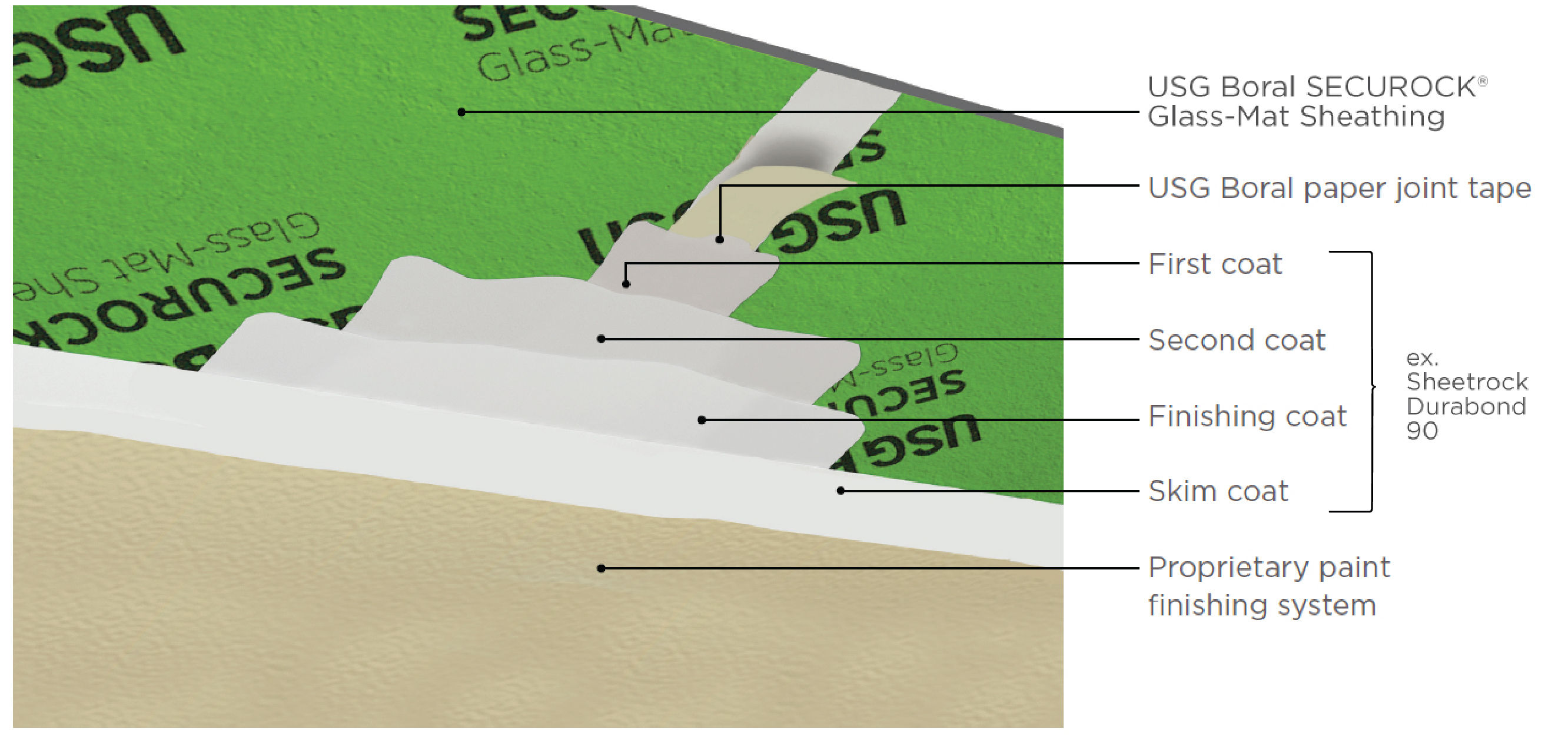

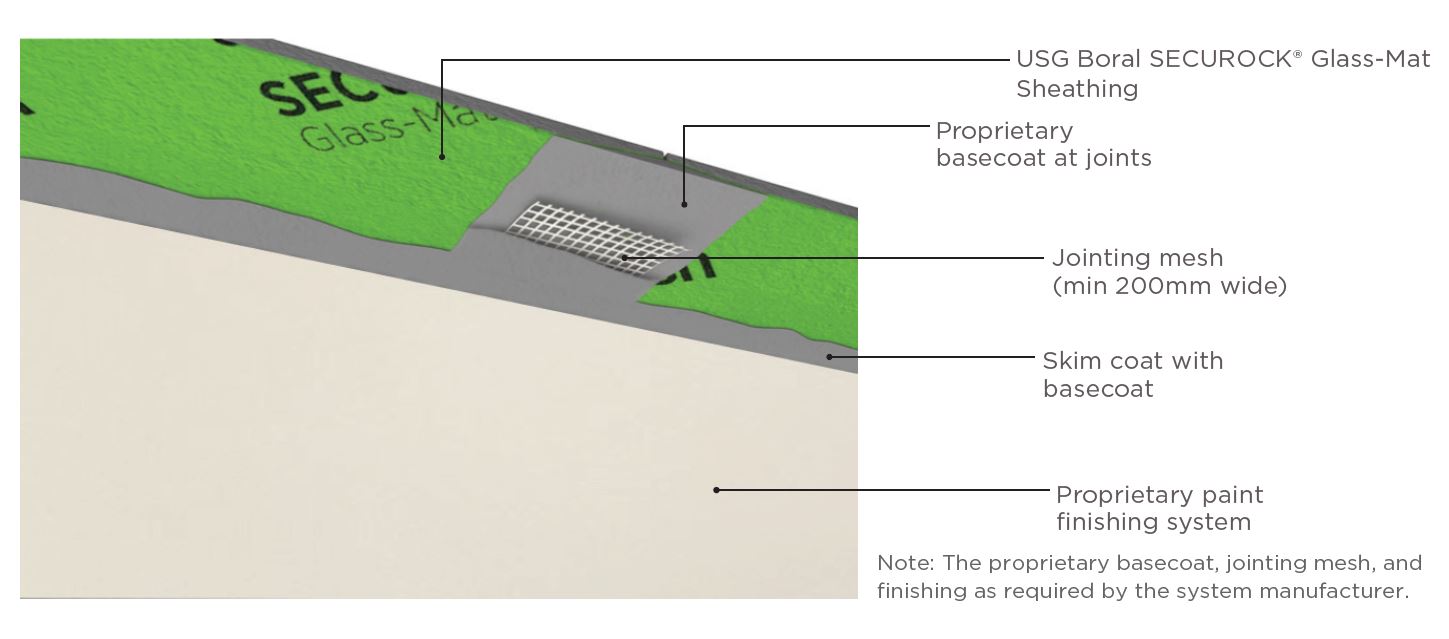

- Level 5 can be achieved for paint finishing (walls and ceilings)

- Supports tiling up to 75 kg/m2 (interior walls)

- For exterior walls finishing, please contact your USGKnauf representative.

- Exceeds requirements for both cementitious and acrylic adhesives per ASTM c297 and BSEN 12004.

Technical Data and Notes

USGKnauf SECUROCK® Glass-Mat Sheathing

Physical Properties (According to ASTM C1177 and EN 15283-1) |

|

1/2" (12.7mm) USG Boral Securock™ Glass-Mat Sheathing (Interior and Semi-Exterior) |

5/8" (15.9mm) USG Boral Securock™ Glass-Mat Sheathing Type F and Firecode™ X (Could be used for exterior walls) |

| Thickness, in. (mm) | |

| 1/2" (12.7mm) | 5/8" (15.9mm) |

| Width and Lengths, mm. (ft) | |

| 1220mm x 2440mm 1200mm x 2400mm |

1220mm x 2440mm 1200mm x 2400mm |

| Weight, nominal (kg/m2) | |

| 11.0 ± 0.5 | 13.6 ± 0.6 |

| Flexural strength, parallel, lbf. (N) | |

| >80 (356) | >140 (445) |

| Flexural strength, perpendicular, lbf. (N) | |

| >140 (445) | >140 (623) |

| *R-Value – Thermal resistance (m2.K/W) | |

| 0.05 | 0.06 |

| Reaction to Fire (A1 – EN-13501-1) | |

| Non-combustible | Non-combustible |

| Resistance to growth of mold - ASTM D3273 score | |

| 10/10 | 10/10 |

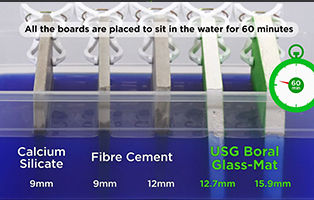

| Water absorption (% of weight) - EN 15283-1 | |

| < 5 % | < 5 % |

Glass-Mat Systems

Interior wall tiling (Non-Direct water exposure)

V2.jpg)

Interior wall tiling (Direct water exposure)

.JPG)

Non - Tile Wall

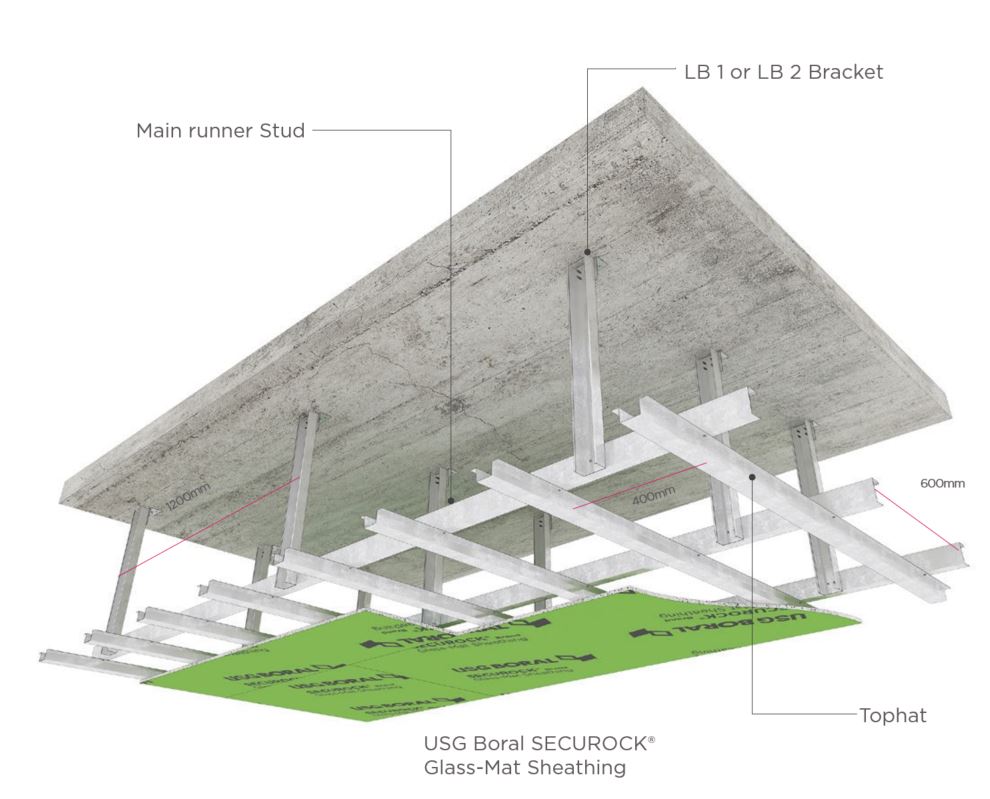

Interior Ceiling Systems - Wet Area

Interior Ceiling Systems - Harsh Environment

Exterior Ceiling Systems - Small Area (<3m)

Exterior Ceiling Systems - Big Area (>3m)